MEFO-Vario

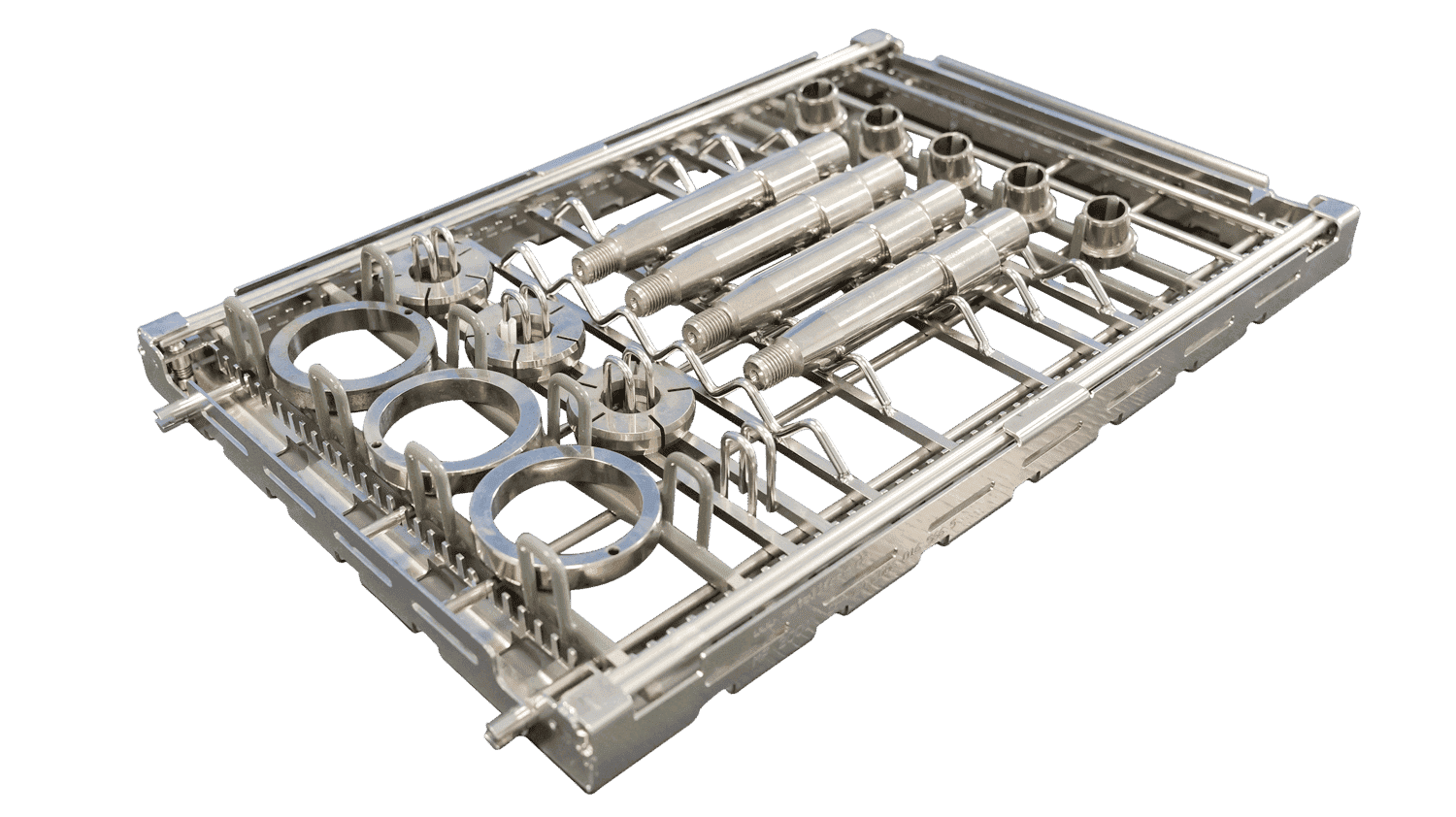

The off-the-shelf workpiece carrier system with maximum flexibility

The highest cleanliness requirements are placed on precision components. In the run-up to series production, cleaning tests are already carried out with prototypes, sample parts and pilot series in order to determine any potential for optimizing the parts design.

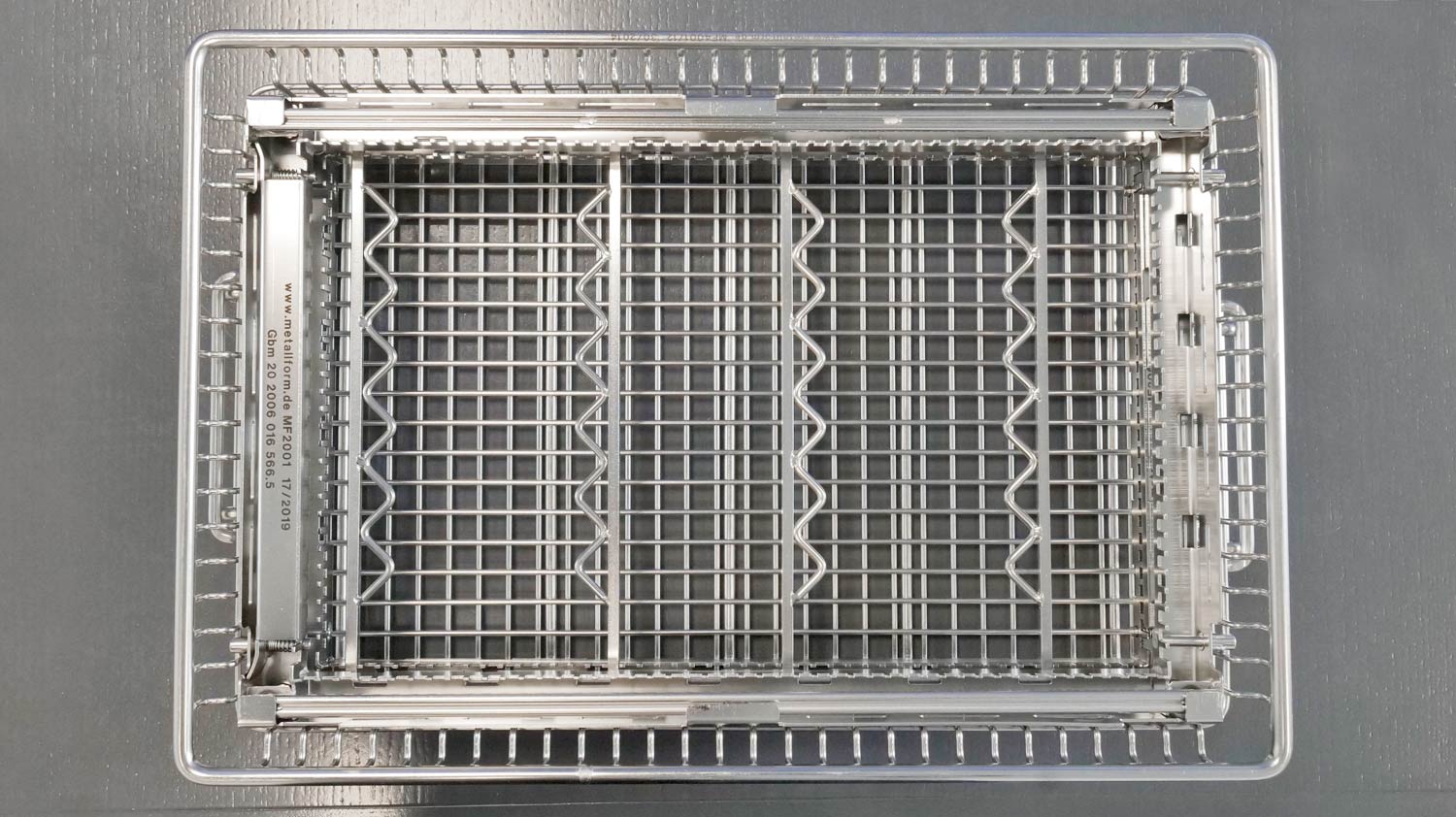

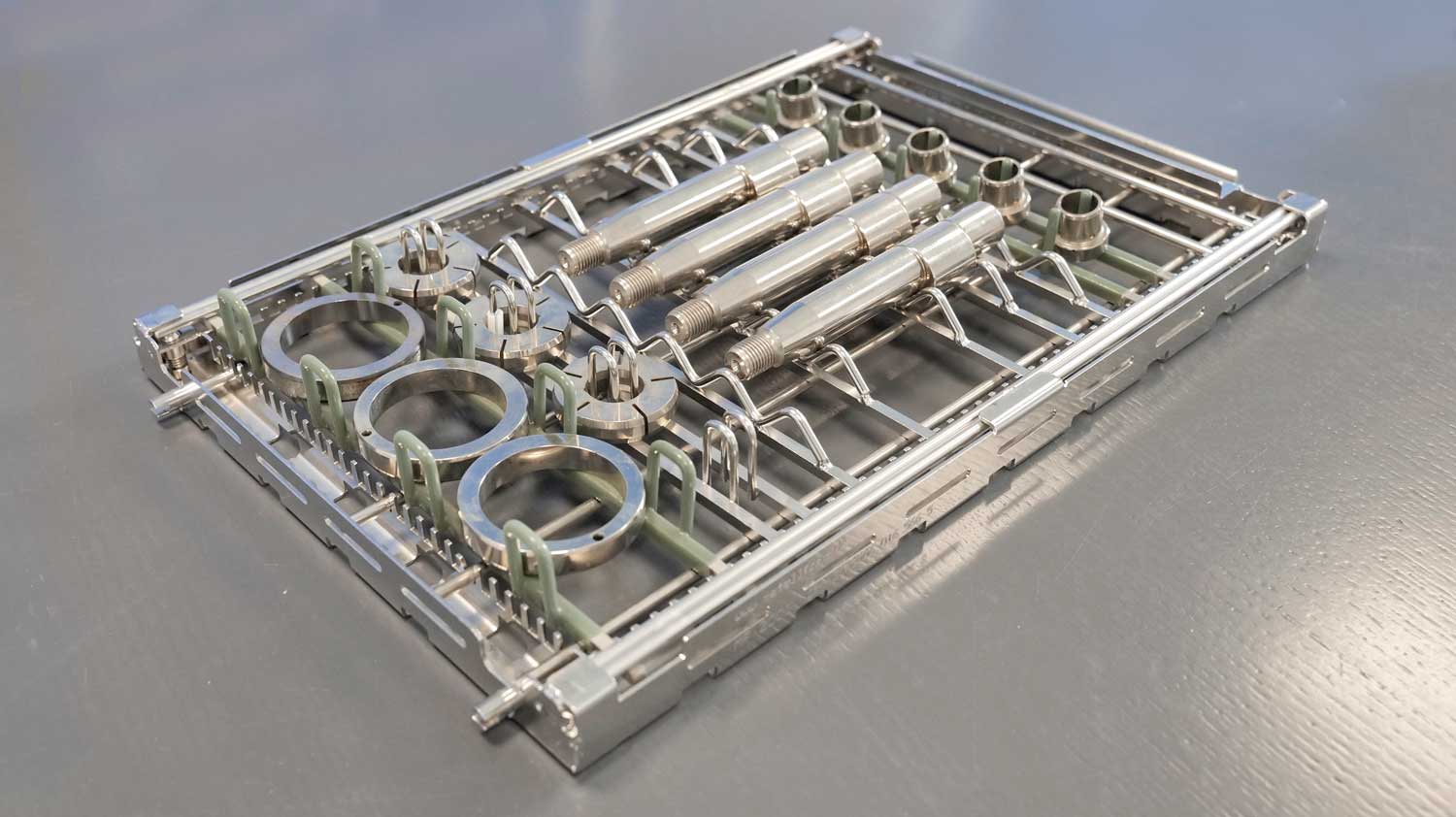

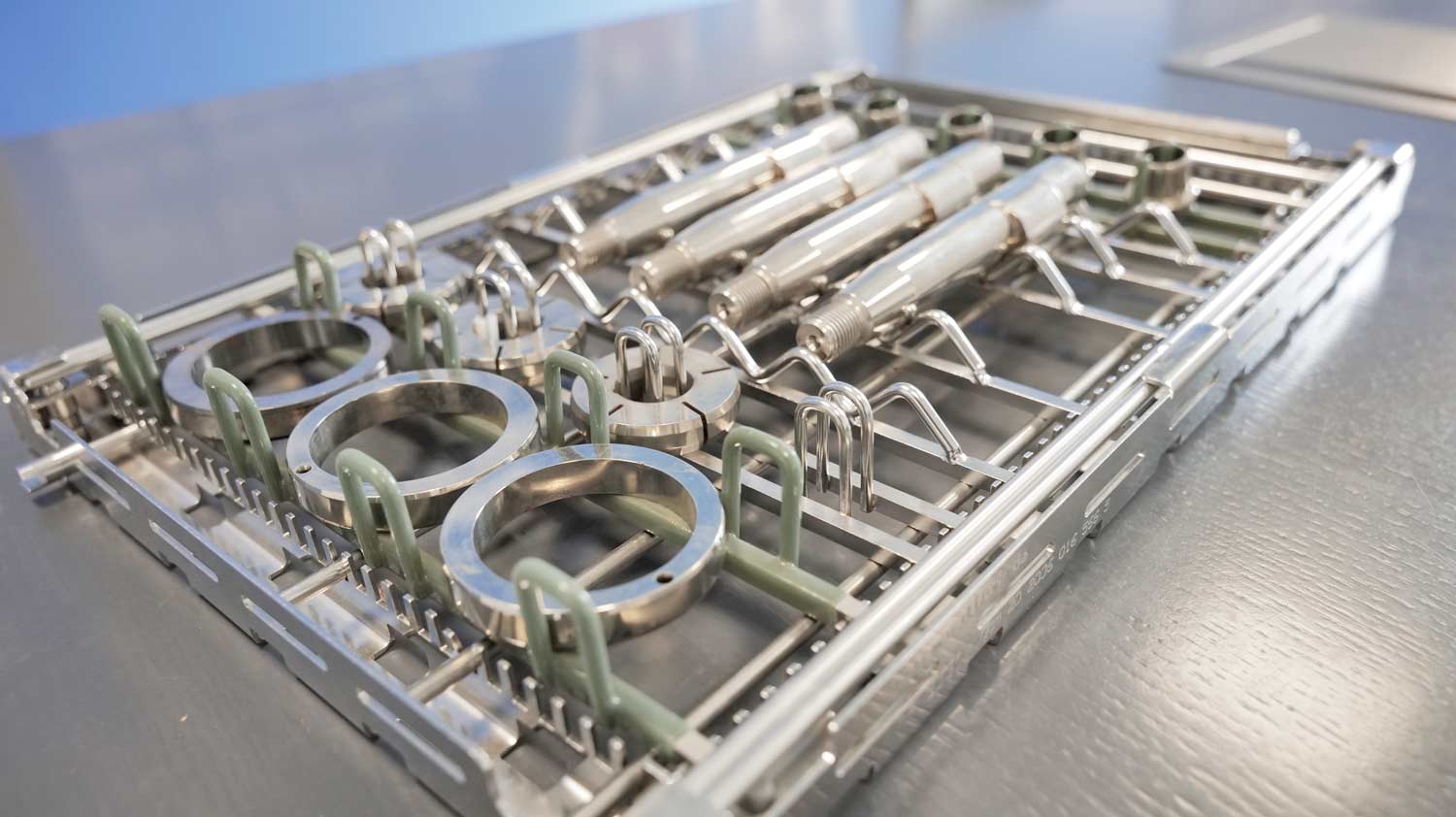

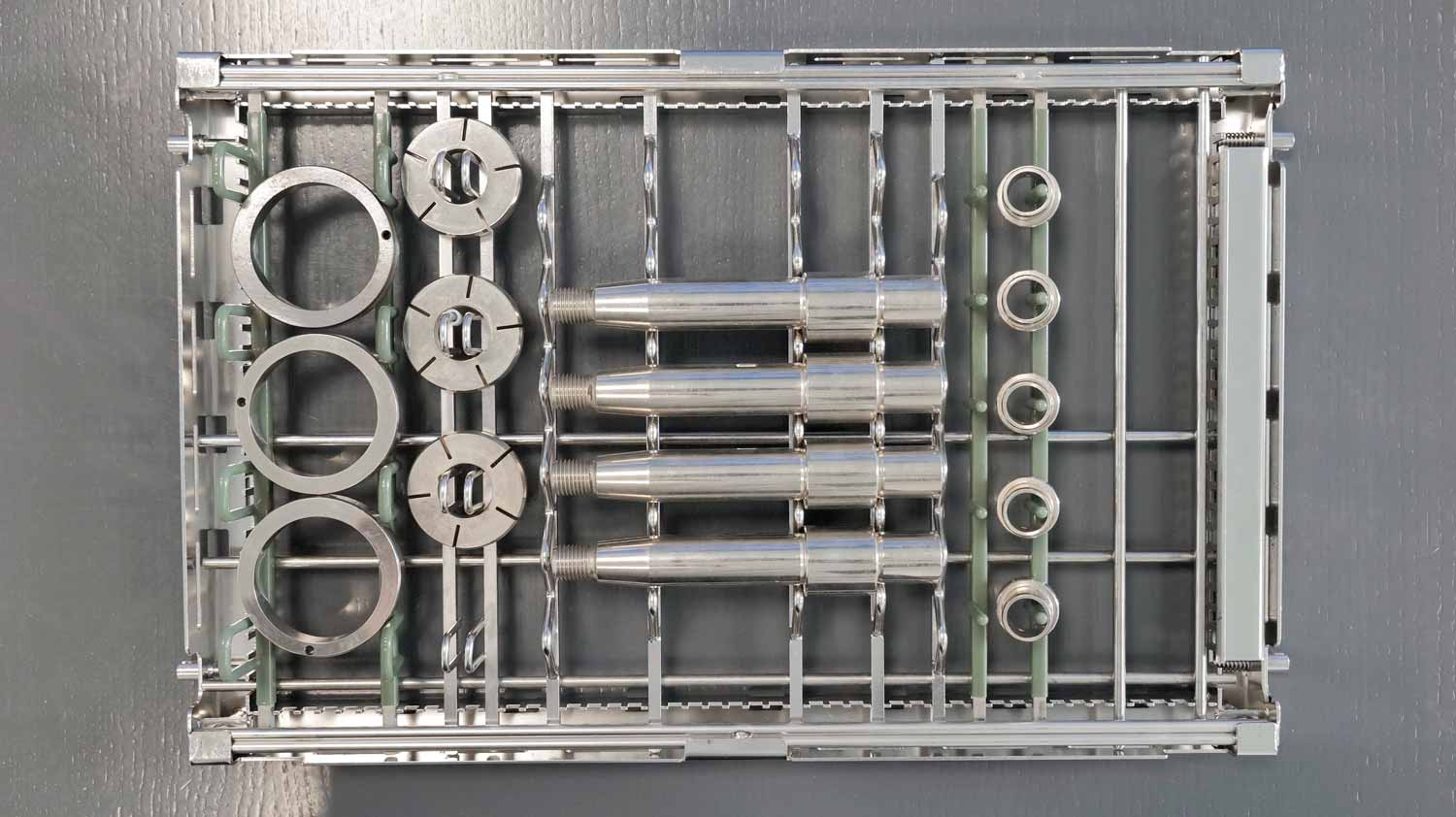

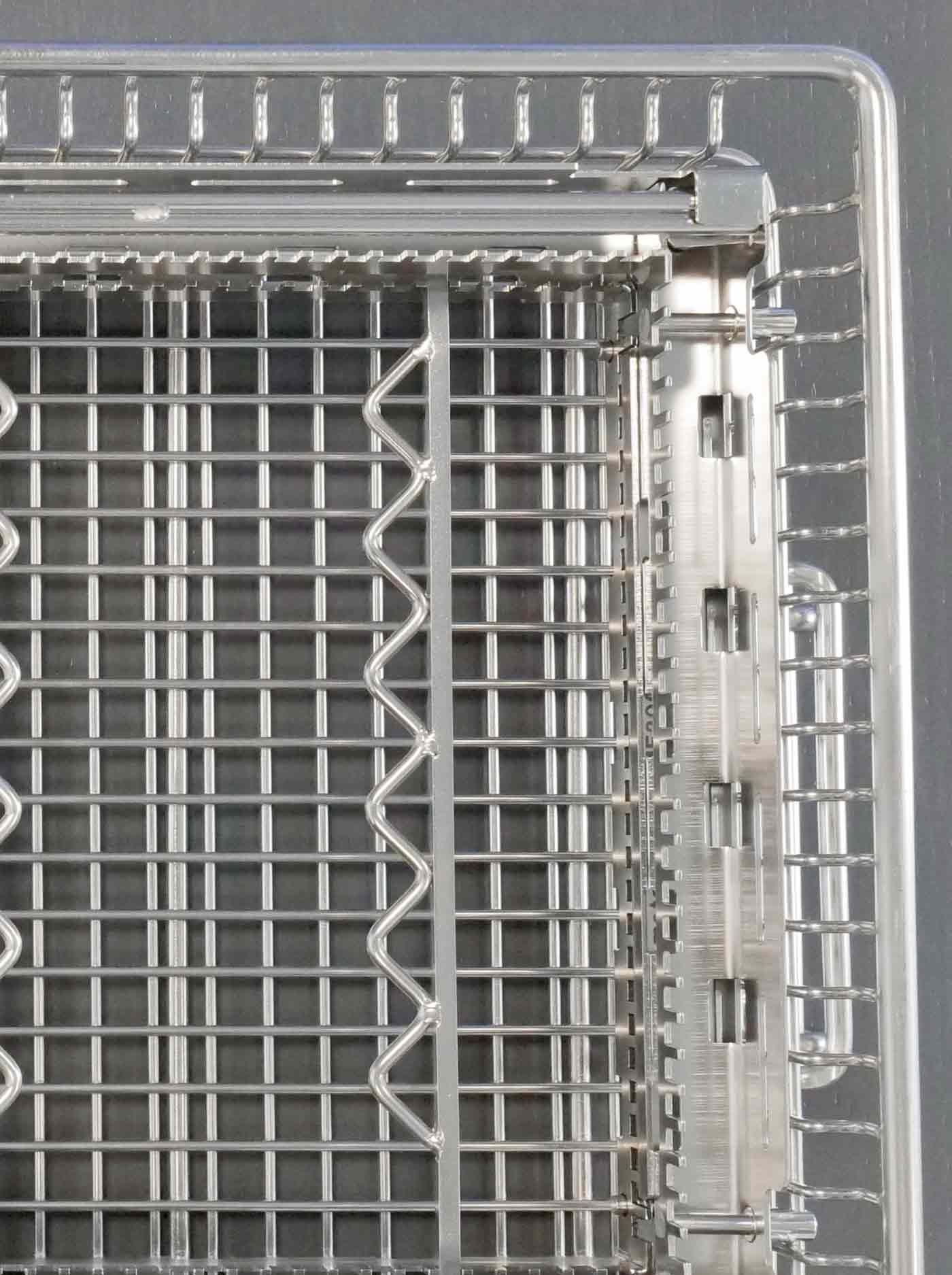

Part-specific workpiece carriers are suitable for this task, as they are also required for cleaning demanding workpieces in small series. With the flexible MEFO-VARIO workpiece carrier system, you can build part-specific compartment, pin, loop or prism trays quickly and without tools using just a few standard components. MEFO-VARIO is used in combination with our MEFO-BOX.

Components

MEFO-VARIO