Part-specific workpiece holders

Perfectly matched

Your requirements can best be met with part-specific workpiece holders? Here we distinguish between the following designs

- Workpiece holders for one specific part

- Workpiece holders for part families

- Workpiece holders for kits

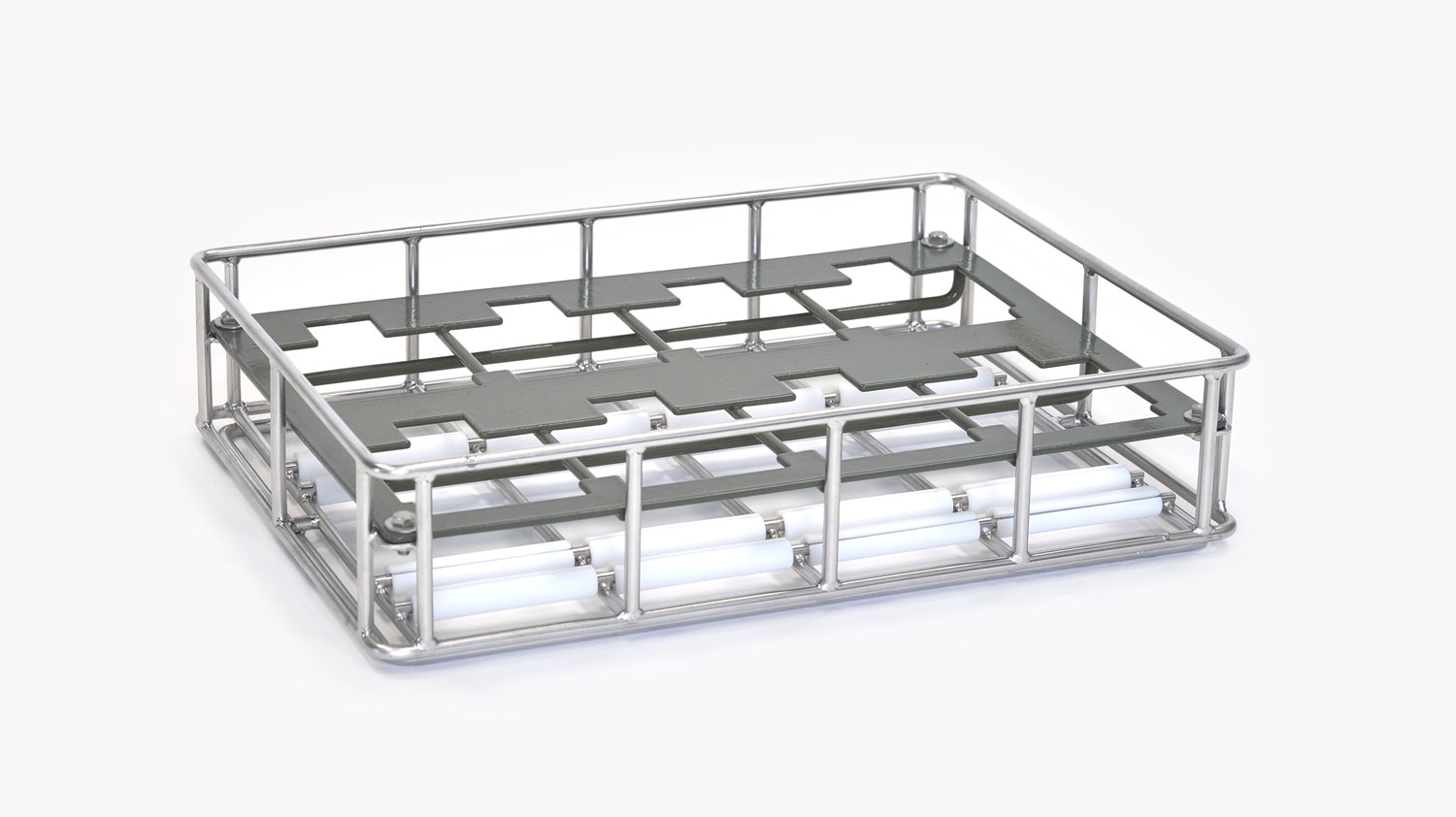

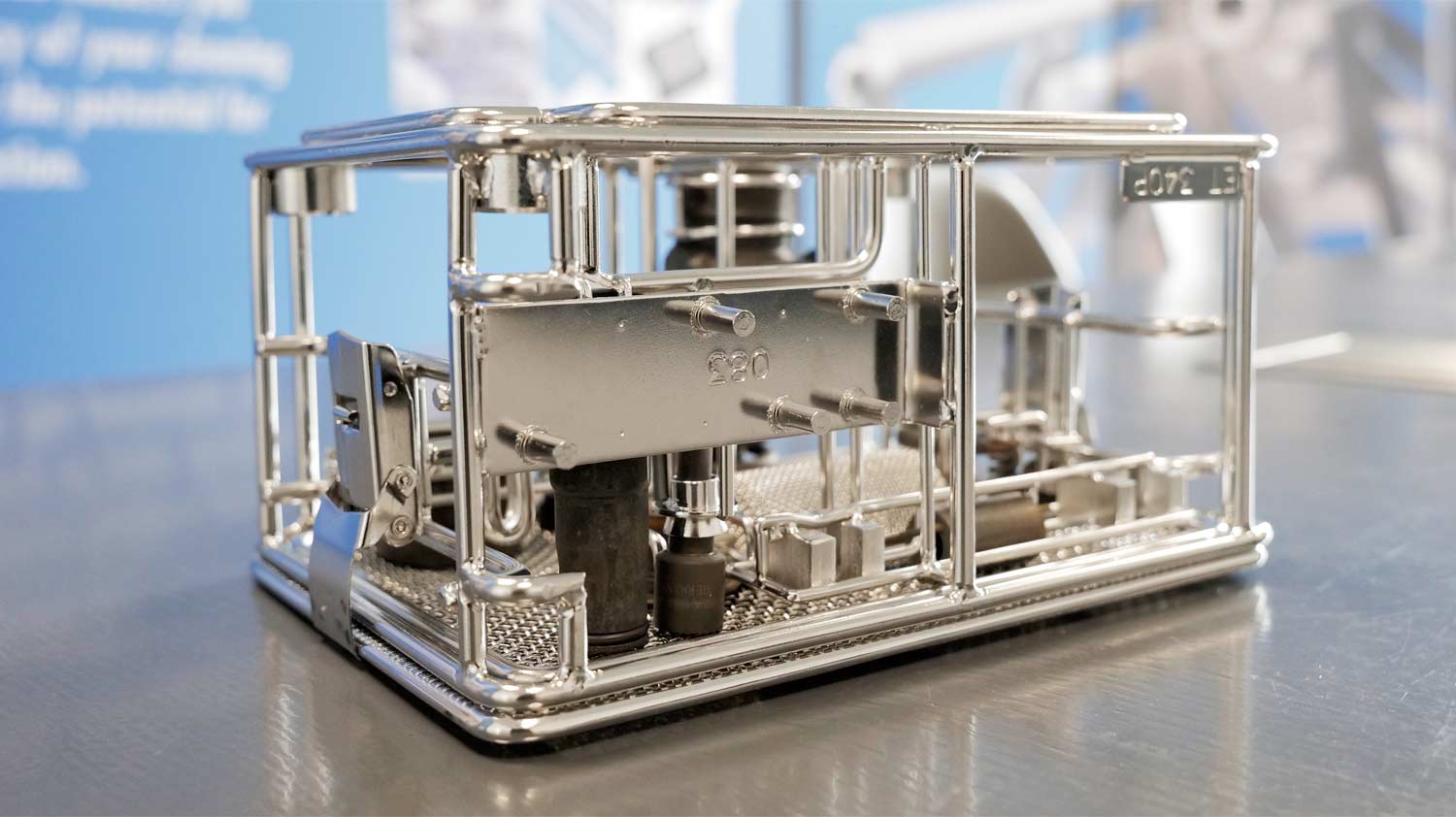

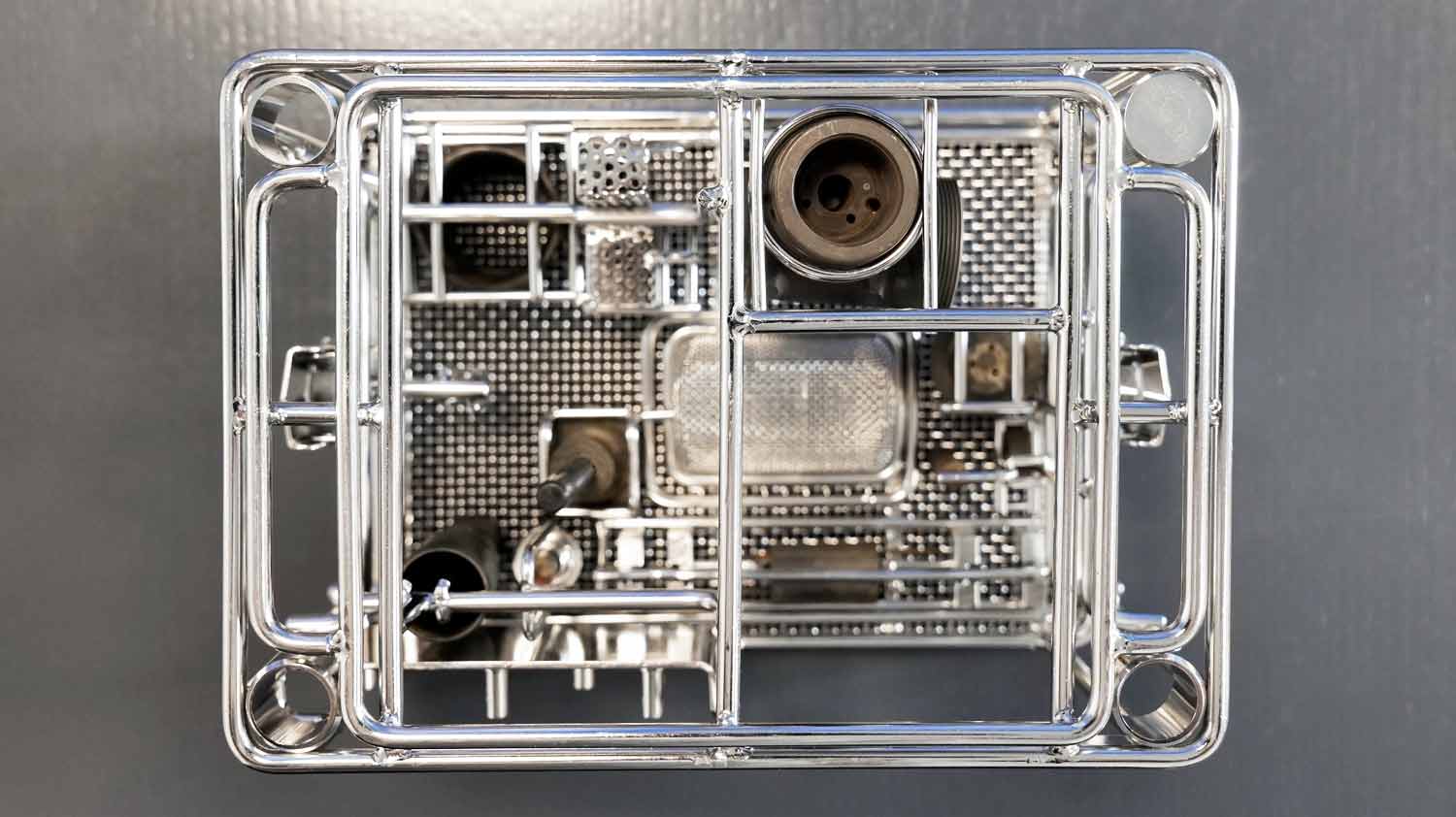

Workpiece holders for a specific component

With these workpiece holders, you optimally protect critical surfaces and achieve maximum throughput. Further handling steps, such as automatic assembly from the workpiece holder or adjustment to a packaging container (blister pack), can be taken into account. This allows a complete component batch to be unloaded directly from the blister to the workpiece holder and vice versa. The workpiece holder for a specific component offers maximum process reliability and can also be designed as a “Poka Yoke” solution if required.

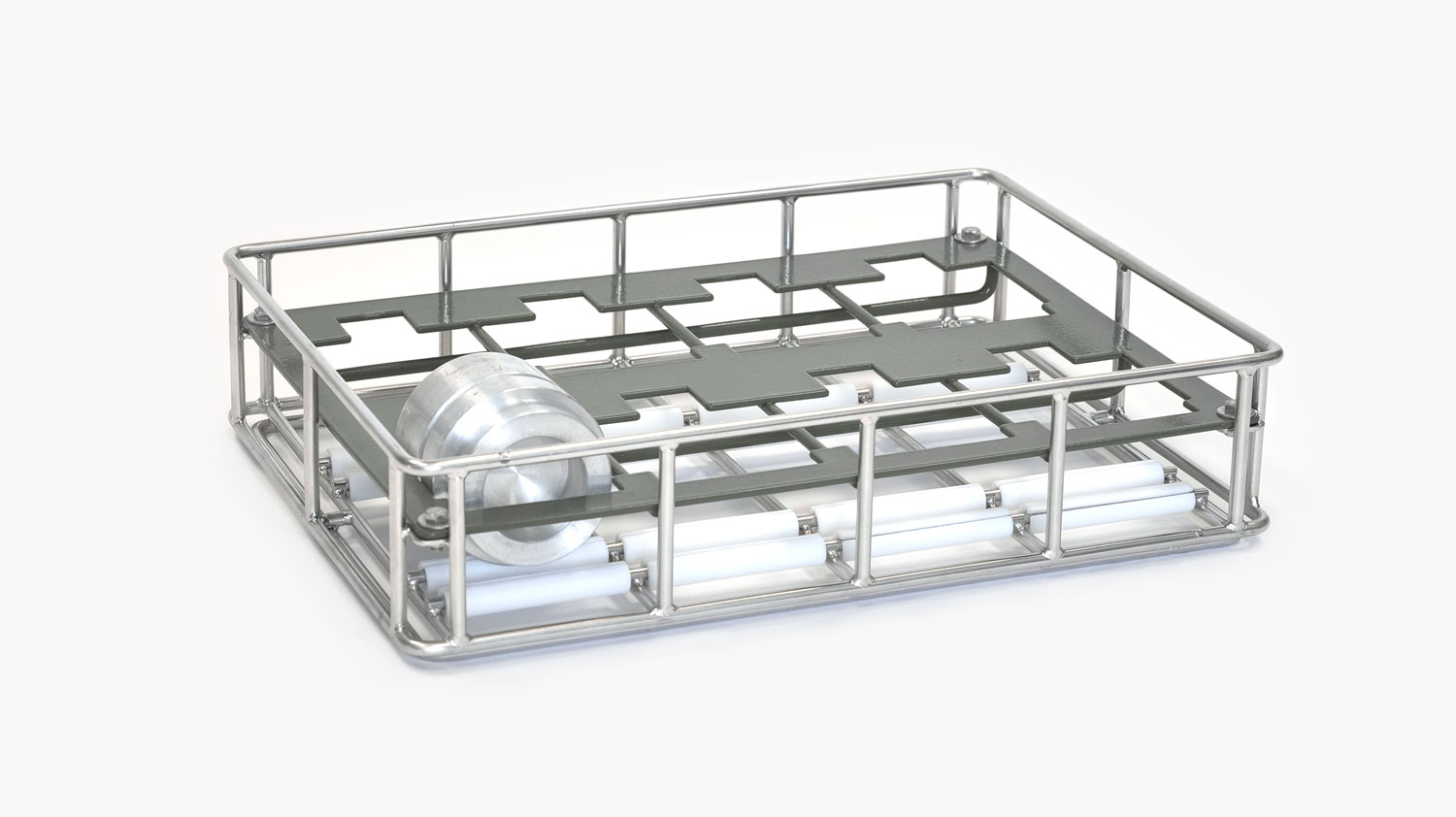

Workpiece holders

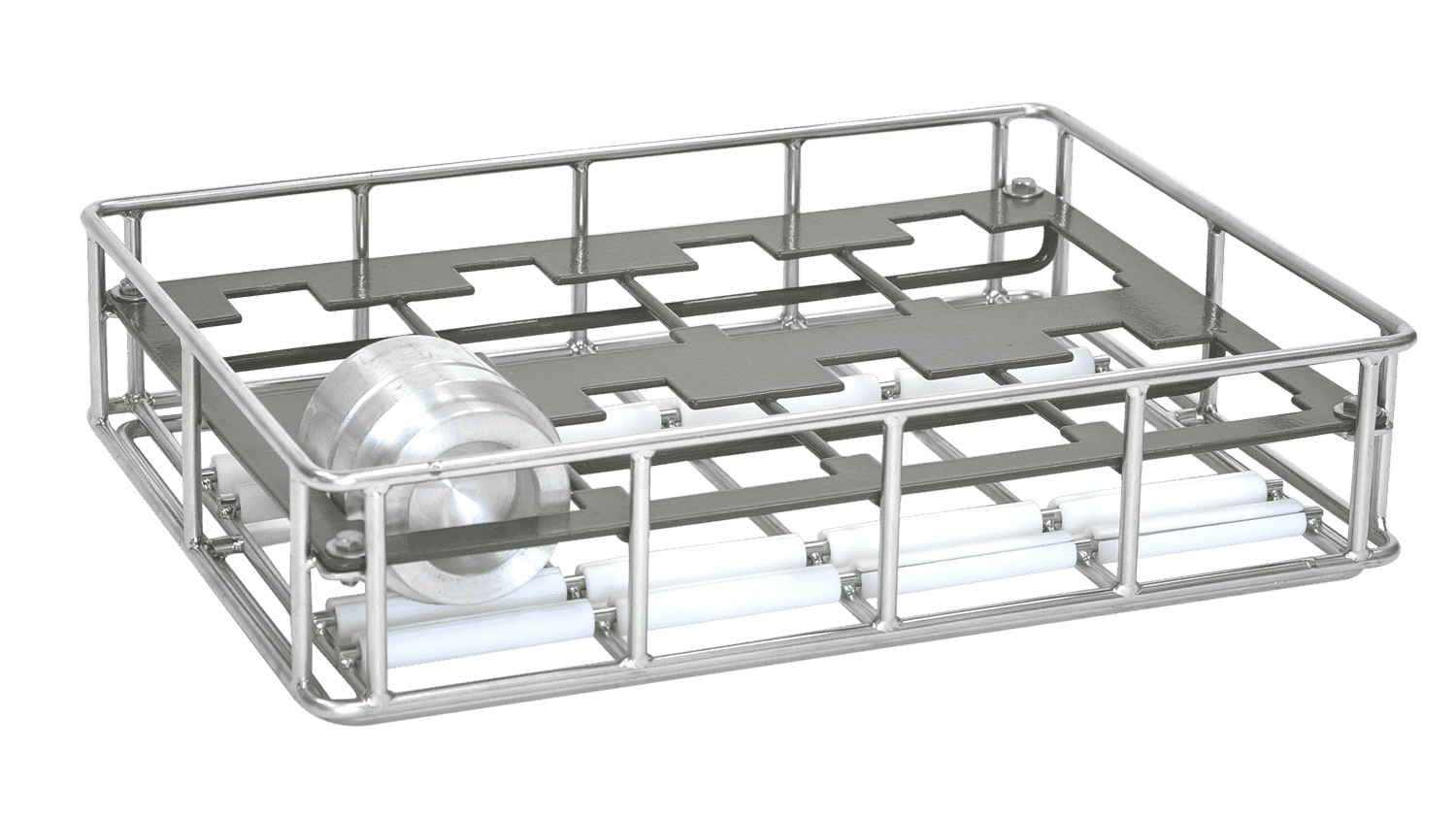

for part families

To minimize the number of workpiece holders required, they are designed for part families whose components have similarities (e.g. disc-shaped, shaft-shaped or cubical parts, identical hole pattern, etc.). Depending on the application, several similar components can be accommodated via adjustable part receptacles, interchangeable inserts, height-adjustable covers or similar.

With our workpiece holders for part families, you need fewer workpiece holders, which reduces investment costs and the required storage space. Since new parts with similar geometry can often also be cleaned in the existing system without any problems, these workpiece holders also offer a high degree of future security.

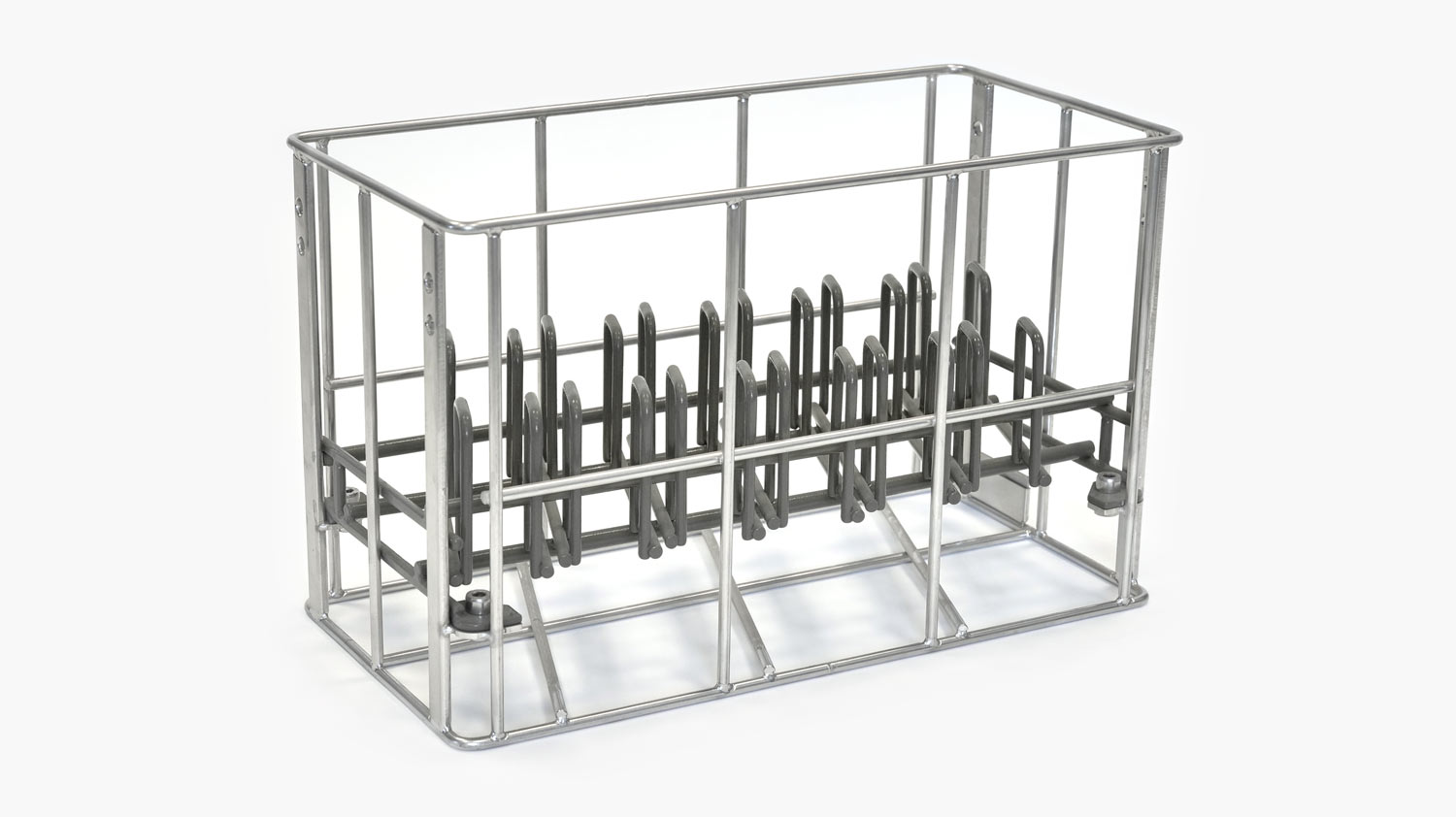

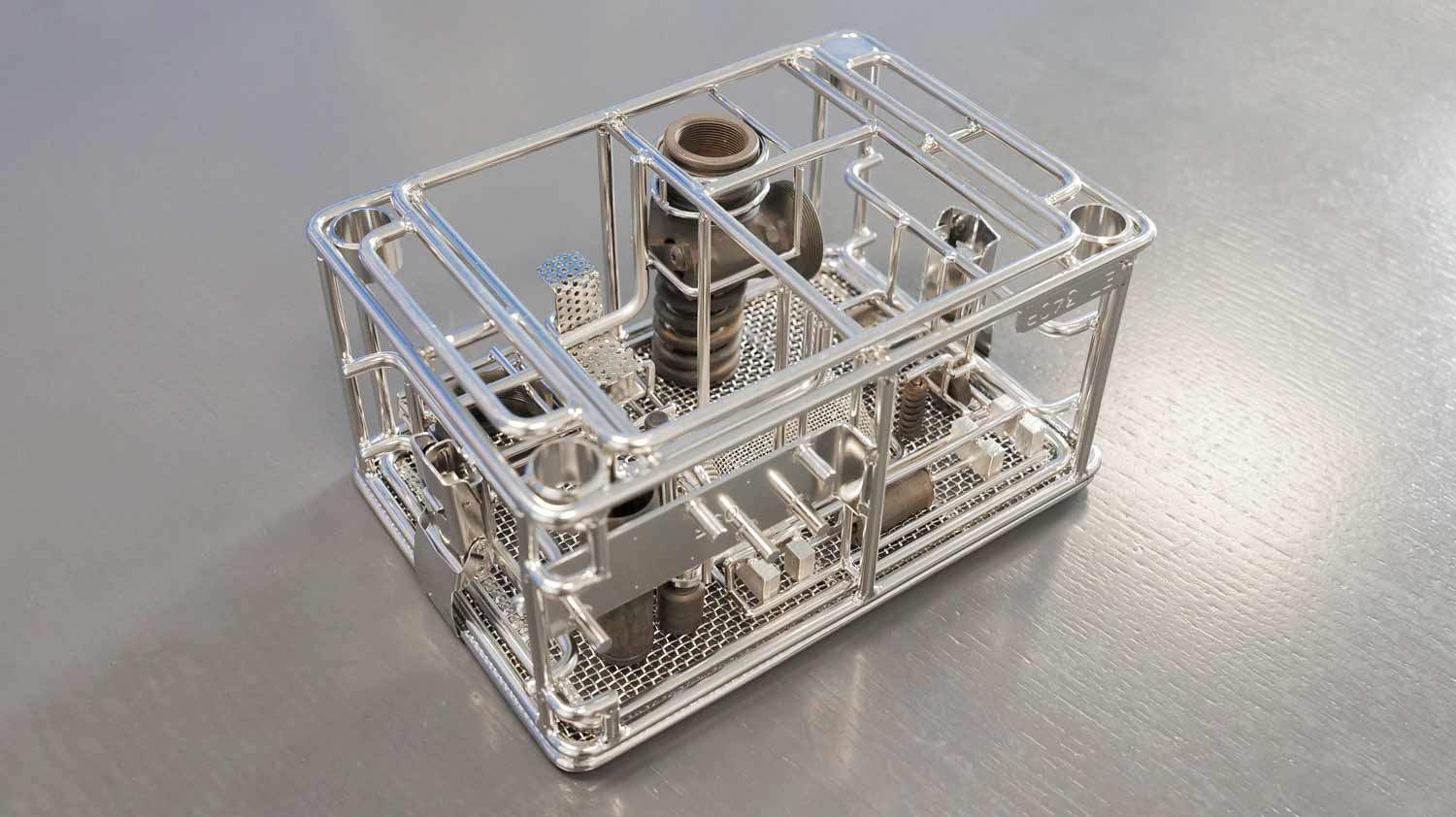

Workpiece holders

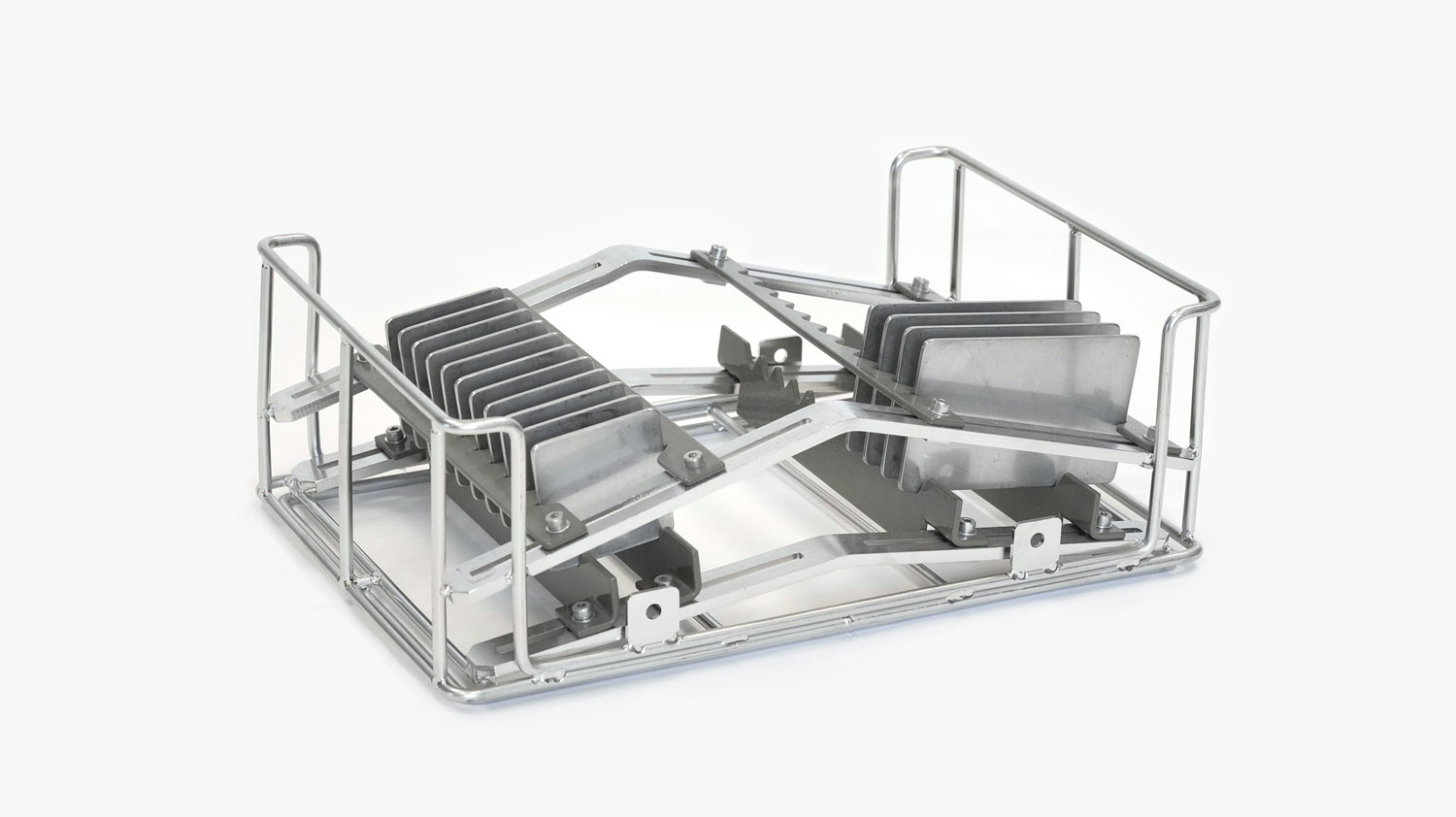

for kits

Workpiece holders for kits – so-called kit trays – are used to accomodate all the individual parts of an assembly. In kit trays, the various individual parts of assemblies consisting of two to x parts can be compiled in a workpiece holder before cleaning, cleaned and then transported in this kit tray to the assembly area. The part receptacles for the individual parts are part-specific.

In the actual assembly process, for example in laser technology or medical engineering or in the production of injection pumps or aircraft landing gear, kit trays offer numerous advantages. Since the workpieces for the respective product are delivered complete as a kit, assembly no longer has to be interrupted due to missing components. Compared to a sorted delivery of the parts, assembly can be accelerated significantly, as there is no longer any time-consuming picking from different containers. At the same time, the use of kit trays reduces the space required at the assembly areas.

Optimization potential can also be utilized with kit trays, for example when new component assemblies have to be disassembled as a result of a faulty component or used component assemblies have to be disassembled for maintenance. In these cases, they ensure that all parts of the disassembled component stay together and that defective parts can be exchanged. Another area of application is the reprocessing of assemblies such as gears or motors. Here, the compilation of the different components in a kit tray eliminates subsequent mix-ups.

Part-specific accessories holders are recommended for: